|

I. Features and applications

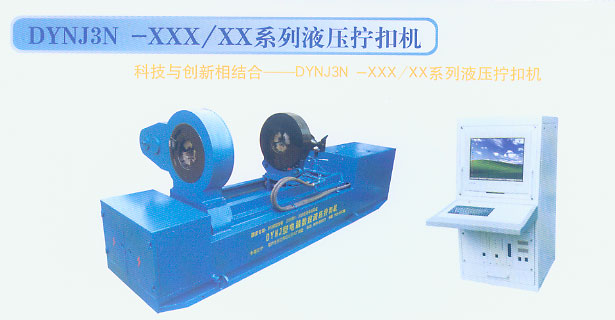

DYNJ3N - XXX / XX series hydraulic screw-on machines are improved products of YNJ - series interlaced hyperboloid clamping mechanism hydraulic screw-on machines of our factory, their clamping mechanism adopts sharing three- curved surface and six-point clamping (In case of big caliber, can be modified as multipoint clamping. Since 3-jaw plate and multipoint clamping mechanism is adopted, its self-centering effect is ideal. Multiple clamping points make radial stress on work piece (pipe body) is even, preventing pipe body from deformation. Since electromechanical integration structure is adopted, it is featured by simple and handsome structure and convenient operation. These machines can be designed according to customer requirements to meet the requirements for the range of different calibers

The control system of this machine mainly adopt imported PLC as lower computer-based full automatic control, and adopts industrial control computer as upper computer. It is equipped with man-machine interface and computer real-time monitoring system, which can make real-time display of torque, make-up position and history curve and value, accumulate records and save various parameters, search original records and have daily report and monthly report saving and printing functions. At the time of working, after various parameters (such as pipe number, caliber, wall thickness, grade of steel, upper limit of torque, lower limit of torque, position, date, operator number) have been set up according to API standard, oil pipes are automatically delivered into equipment through driven line; after automatically completing make-up work and reaching the preset torque and make-up position, it automatically stop and loosen, then oil pipes automatically exit to driven line; In case of unacceptable quality, the system sends acoustic and visual alarm. Therefore, it can provide double guarantee for the make-up quality of oil pipe. The main back-up tong is featured by big clamping range, adjustable speed, high operational efficiency and convenient operation and use. Since this series screw-on machine adopts full automatic control, equipment is featured by small abrasion and long performance life. This series screw-on machine is mainly applicable to the flow process of the installation and coupling production line for oil pipe, casing and oil-well pump (can be connected with user's driven line according to customer requirements)

II. Performance parameters:

| Model: DYNJ3N¡ª |

200/20 |

220/30 |

240/40 |

280/50 |

380/80 |

400/100 |

550/100 |

| Rated torque: KN.m |

20 |

30 |

40 |

50 |

80 |

100 |

100 |

| Rated revolutions: r/min |

8~50 |

7~45 |

6~30 |

5~28 |

4~25 |

3~20 |

3~15 |

| Drift diameter: mm |

200 |

220 |

240 |

280 |

380 |

400 |

550 |

| Scope of application: mm |

60~178 |

73~196 |

89~229 |

114~245 |

139~339 |

178~365 |

245~430 |

| Rated pressure: Mpa |

16 |

16 |

16 |

16 |

16 |

16 |

16 |

| Rated flow : l/min |

75 |

75 |

135 |

135 |

135 |

135 |

135 |

| Center height: mm |

800 |

980 |

1100 |

1110 |

1125 |

1250 |

1350 |

| Total power: Kw |

18.5 |

18.5 |

30 |

30 |

45 |

45 |

45 |

| Total weight: Kg |

3500 |

3600 |

7800 |

8200 |

9200 |

9500 |

9800 |

Huludao Liaoxi Petroleum Machines & Tools Factory

Contact Mode:

Unit: Huludao Liaoxi Petroleum Machines & Tools Factory Address: North of road,100m ahead of east exit of expressway, Huludao City, Liaoning Province

Tel: 0429-2553588,2606273 Fax : 0429-2624866

Mobile: 18842935580 13909893705 Postal Code: 125001 |